HBT

Hybride Wälzlager haben viele Vorteile. Erst recht, wenn sie nicht rosten.

Schmutz, Nässe, hohe Temperaturen, Säuren und viele andere äußere Einflüsse: Es gibt jede Menge widriger Umgebungs-bedingungen, die mechanischen Bauteilen zuwider sind. HTBNIROHYBRID Radialrillenkugellager sind wie gemacht für extreme Bedingungen.

Denn sie sind resistent gegen nahezu allen widrigen Einflüssen.

Keramik ist der älteste Werkstoff der Menschheit. Dessen Eigenschaften sind allerdings moderner denn je.

HTBCERAMIC Wälzlager werden überall dort gebraucht, wo konventionelle und hybride Lager versagen.

Aggressive Umgebungsmedien wie Wasser, Säuren, Laugen und Gase, aber auch extreme Temperaturen können Vollkeramiklagern nichts anhaben.

Vollkeramische Wälzlager können ohne Schmierstoff verwendet werden. Das schont die Umwelt und den Geldbeutel.

Weitere Vorteile sind die stromisolierenden und antimagnetischen Eigenschaften der verwendeten Keramiken.

Keramikwälzlager aus ZRO2 und SI3N4 sind nicht toxisch und somit etwa im Bereich der Lebensmittel- und Pharmaproduktion eine optimale Alternative zu konventionellen Lagern.

Aufgrund ihres bis 40% geringeren Gewichts -verglichen mit Lagern aus Stahl- sind vollkeramische Wälzlager ideal für den Einsatz in der Luft- und Raumfahrt. Zudem haben vollkeramische Lager deutlich höhere zulässige Drehzahlwerte.

Sparen Sie wertvolle Zeit – kontaktieren Sie uns direkt!

Wir überhäufen Sie nicht mit Datenblättern und unnötigen Informationen. Bei uns erhalten Sie eine individuelle Beratung, die auf Ihre Probleme abgestimmt ist.

Wir sind darauf spezialisiert, Lösungen für die Anwendungsprobleme unserer Kunden zu finden und sparen so Ihre wertvolle Zeit!

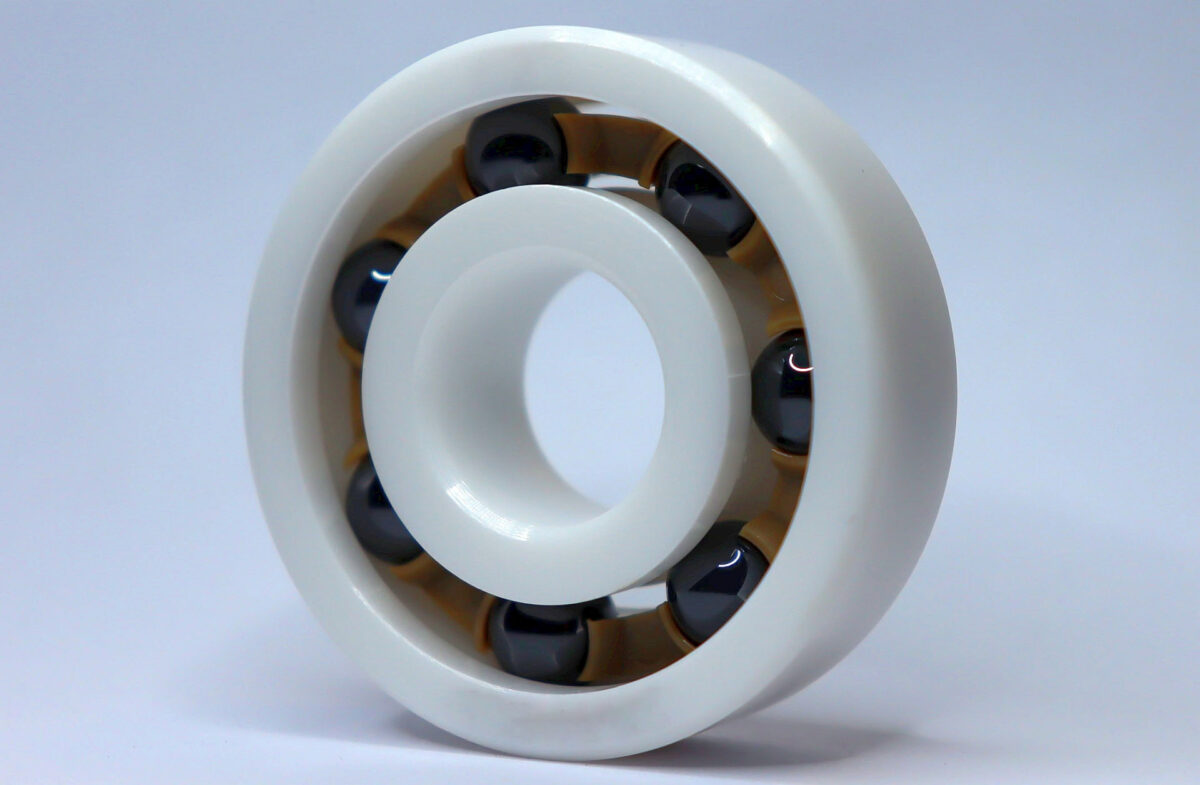

Hybride Wälzlager haben viele Vorteile.

Erst Recht, wenn sie nicht rosten.

Schmutz, Nässe, hohe Temperaturen, Säuren und viele andere äußere Einflüsse: Es gibt jede Menge widriger Umgebungs-bedingungen, die mechanischen Bauteilen zuwider sind. HTBNIROHYBRID Radialrillenkugellager sind wie gemacht für extreme Bedingungen. Denn sie sind resistent gegen nahezu allen widrigen Einflüssen.

- X105CrMO17 ist ein nichtrostender Stahlmit exzellenten Eigenschaften, welche ihnfür die Lagerringe prädestiniert. Mit einerHärte von bis zu 60 HRC (Rockwell) ist dieVerschleißneigung sehr gering.

- Siliziumnitrid (SI3N4) ist das perfekteMaterial für Kugeln und andereWälzkörper. Extrem hart, perfekteOberflächenstruktur, minimale Wärme-ausdehnung und Verformungsneigung.

Hybride nichtrostende Lager der HTBNIROHYBRID Reihe sind perfekt für alle Anwendungen, bei denen konventionelle Lager an ihre Grenzen stoßen. Oder gänzlich versagen.

Anwendungsbereiche unserer Produkte

Zu den Anwendungsbereichen unserer Produkte zählen unter anderem die folgenden Industriezweige:

- Technologie

- Kugellager

- Lebensmittel

- Medizin

- Stahlindustrie

- Windkraft

Technologie

Kugellager

Lebensmittel

Medizin

Lebensmittel

Technologie

Stahlindustrie

Windkraft

wenn es um höchste

Anforderungen geht!

wenn es um höchste

Anforderungen geht! Ihr direkter Kontakt zu uns!

- 05931 / 885485

- info@mg-ceramics.com