Ceramic bearings for the food industry – durable precision for the highest hygiene standards

Ceramic bearings from MG Ceramics are the hygienic, maintenance-free, and durable solution for demanding applications in the food industry – wherever precision, reliability, and cleanliness are crucial.

Definition / Overview

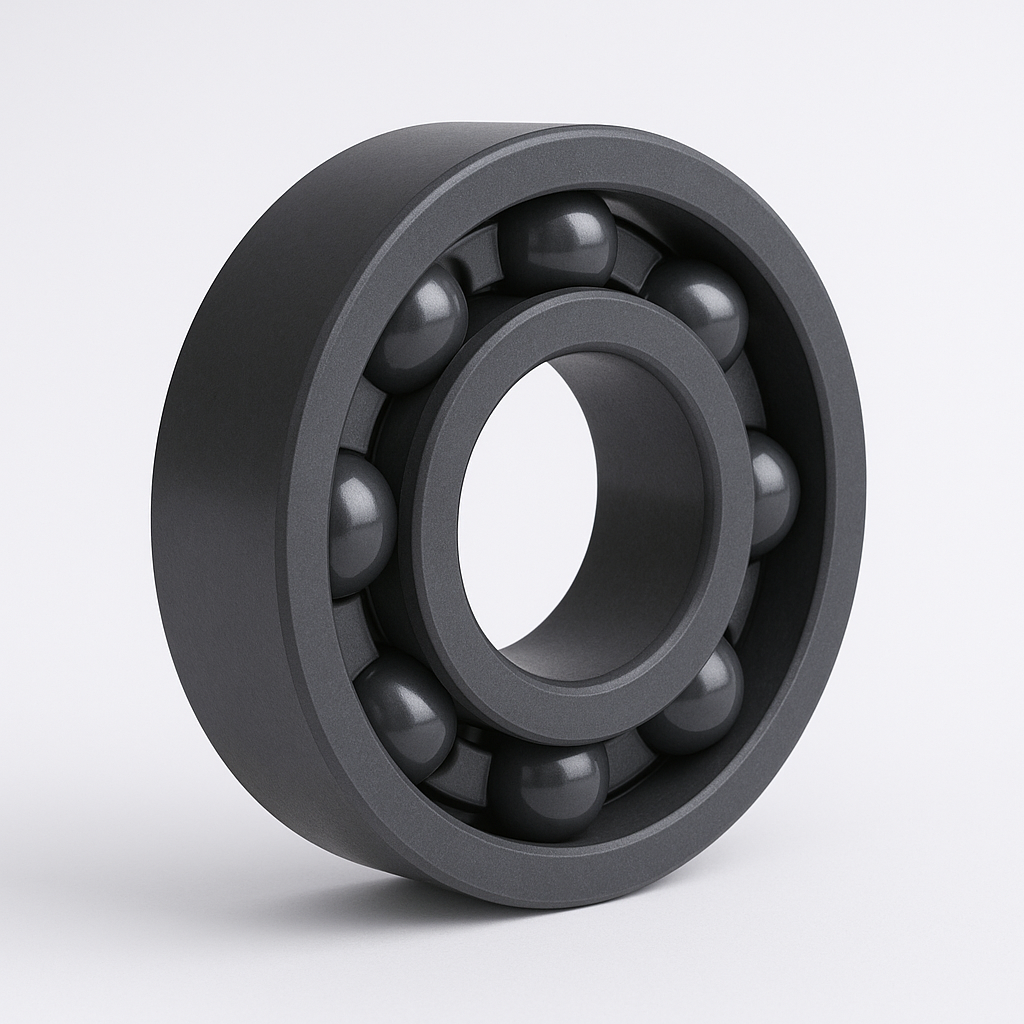

Ceramic bearings are high-precision bearing solutions made from high-performance technical ceramics, which have been specially developed for environments with high hygiene requirements. In the food industry, they are increasingly replacing conventional stainless steel or plastic bearings, as they offer numerous advantages in terms of durability, chemical resistance, and temperature resistance.

Thanks to the use of special ceramic materials such as zirconium oxide or silicon nitride, these bearings are completely corrosion-free, resistant to acids and cleaning chemicals, and therefore ideal for machines, systems, and conveyor technology in food processing.

Advantages of ceramic bearings in the food industry

Ceramic bearings from MG Ceramics impress with their combination of technical precision and maximum hygiene. They offer decisive advantages for plant engineers and maintenance managers:

- Food-safe and hygienic: Free of metallic residues and completely resistant to cleaning agents.

Maintenance-free: No regreasing required – ideal for hygienically sensitive areas.

Durable: Significantly longer service life than stainless steel alternatives.

Acid-resistant: Resistant to aggressive media, steam, and alkaline solutions

High temperature resistant: Stable operation even at continuous ambient temperatures of up to 250 °C.

Lightweight: Lower inertia ensures smooth running and lower energy consumption.

This combination makes ceramic bearings an economically and technically compelling choice for manufacturers of production and filling equipment, packaging machines, or conveyor technology in the food industry.

Applications in the food industry - Resistance to temperatures up to 1,000°C

| Area | Typical temperature | Why ceramic bearings are useful |

|---|---|---|

| Ovens and conveyor systems in bakeries | Up to 250–350 °C | Metal bearings are damaged by flour dust and fats; ceramic bearings withstand temperatures and cleaning better. |

| Drying systems (e.g., milk powder, coffee, spices) | 150–300 °C | High exposure to hot air and particles; ceramics are resistant to oxidation and corrosion. |

| Hot filling systems (e.g., canned goods, sauces) | 120–160 °C | Steam sterilization and cleaning cycles with hot water; Ceramics are resistant to thermal shock and chemicals. |

| Roasting plants (coffee, cocoa, nuts) | 200–300 °C, locally higher | Constant heat, dust, aromatic oils – ceramic bearings prevent lubrication problems. |

| Deep-frying lines (snack/French fry production) | Oil temperatures up to 180–200 °C | High continuous heat and oil mist quickly destroy metal bearings. |

| Sterilization and autoclave systems | Up to 130–150 °C, saturated steam | Cleaning and sterilization cycles; ceramics are chemically inert. |

Technology / Application

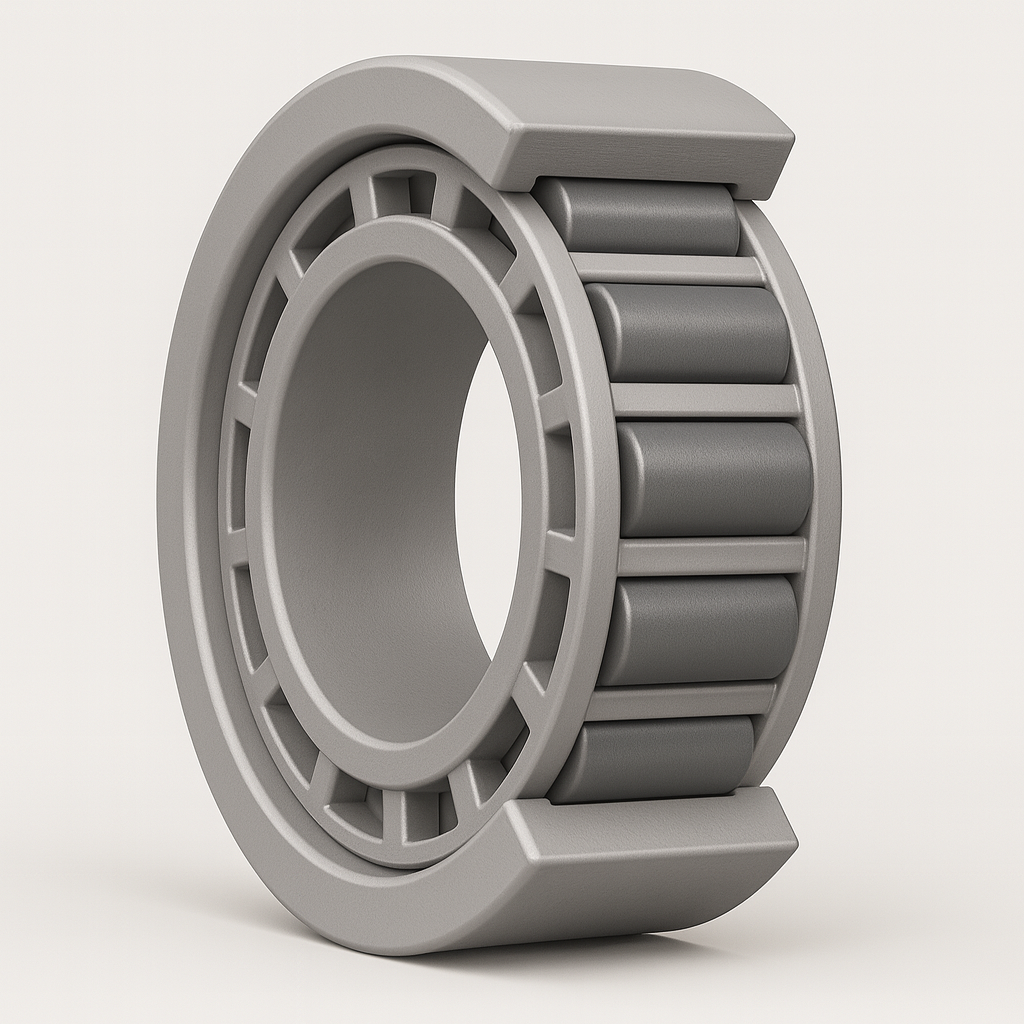

MG Ceramics offers a wide range of ceramic bearing solutions – from miniature bearings to custom-made products for high-performance systems.

Ceramic bearings are used in the food industry, particularly in the following areas:

- Filling systems for beverages and dairy products

Conveyor and packaging systems

Cleaning and sterilization zones

Systems with CIP/SIP processes

Machines with high thermal or chemical loads

Thanks to their high dimensional accuracy and surface quality, ceramic bearings offer consistent performance even under extreme conditions. Their non-metallic construction prevents magnetic influences and at the same time protects against particle abrasion—a crucial aspect for hygienic production lines..

FAQ

Why are ceramic bearings more suitable for the food industry than stainless steel?

Ceramic bearings are completely corrosion-free, chemically inert, and do not require lubrication. This prevents contamination and meets the highest hygiene standards—a clear advantage over stainless steel.

What temperatures can ceramic bearings withstand?

Depending on the material, continuous temperatures of up to 250 °C are possible, and even higher in special designs. This makes them ideal for hot filling and thermal processes.

Are ceramic bearings maintenance-free?

Yes, they do not require relubrication and are therefore particularly economical to operate.

Are ceramic bearings available in special sizes or customer-specific designs?

MG Ceramics manufactures special sizes, hybrid bearings, or special sealing concepts for individual system requirements on request.

Are ceramic bearings certified as food-safe?

Yes, the materials used comply with international standards for food-safe applications and are proven to be harmless.

Summary

Ceramic bearings from MG Ceramics offer a future-proof solution for plant engineers and maintenance managers in the food industry. They combine hygiene, precision, and durability in a maintenance-free system—ideal for applications where safety and efficiency are crucial.

Rely on durable, food-safe storage technology and benefit from the experience of a specialist in the field of high-performance ceramics.

when it comes to the highest

when it comes to the highest

requirements!

Your direct contact with us!

- 05931 / 885485

- info@mg-ceramics.com