HQW

The precision of the spindle is crucial for the performance of a machine tool

decisive!

HQW Precision offers a range of high-accuracy precision bearings that are specifically optimized to meet the requirements of today’s increasingly complex machine tools.

Spindle bearings from HQW Precision

Thin section bearings

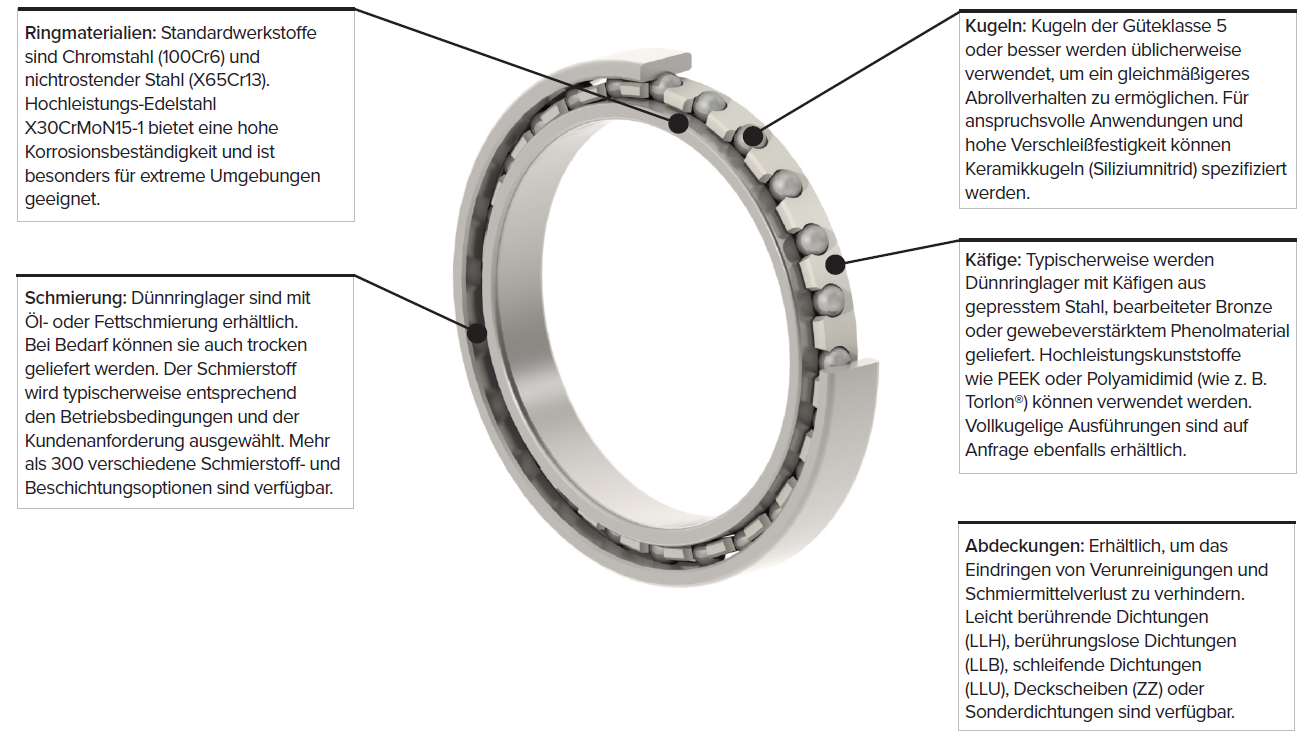

For high-performance applications where space and weight are important considerations, thin section bearings enable smooth rotation, reduced friction and high positioning accuracy in a much smaller space than conventional ball bearings. HQW precision thin section bearings are available in a wide range of sizes, materials and designs and increase flexibility in the design, resulting in more efficient plant design and thus a reduction in

Total system costs.

Save valuable time – contact us directly!

We don’t overwhelm you with data sheets and unnecessary information. With us you will receive individual advice that is tailored to your problems.

We specialize in finding solutions to our customers’ application problems, saving your valuable time!

Other aspects

Application examples

- Aerospace & Defense

- Robotics & Measurement Technology

- Medical systems and devices

- Optical scanning devices

- Food processing plants

- Textile machinery

Precision and quality

Customers can rely on exceptional quality and precision. Precision tolerances conform to ISO P5 (ABEC5) standards as standard, while tolerances of ISO P4 (ABEC7) can be met if required. With world-leading systems and processes, our facilities are fully ISO9001 certified.

Size range & variants

Thin section bearings are available in different series, so bearings with a larger cross-section and high load capacity can be selected without having to increase the shaft diameter.

Various series are available, with sizes ranging from 2mm bore diameter to 180mm outside diameter, both as deep groove ball bearings and angular contact ball bearings.

Special requirements

Custom bearings are available to meet application specific requirements. Special design features such as flanges and housings, special materials and components are possible. Different versions are available for low torques or high load capacities.

when it comes to the highest requirements!

when it comes to the highest requirements!Your direct contact with us!

- 05931 / 885485

- info@mg-ceramics.com